Here is a great piece written by one of the best 2 stroke tuners, Frits Overmars. He and Jans Thiel both worked at Aprilia(along with many others) and helped develop what is arguably the best pound for pound 2 stroke racing engine in the 2 stroke GP era, the RSA 125. Their knowledge is backed up by thousands of dyno tests, hundreds of GP trophies and several world championships. It doesn't get any better than that.

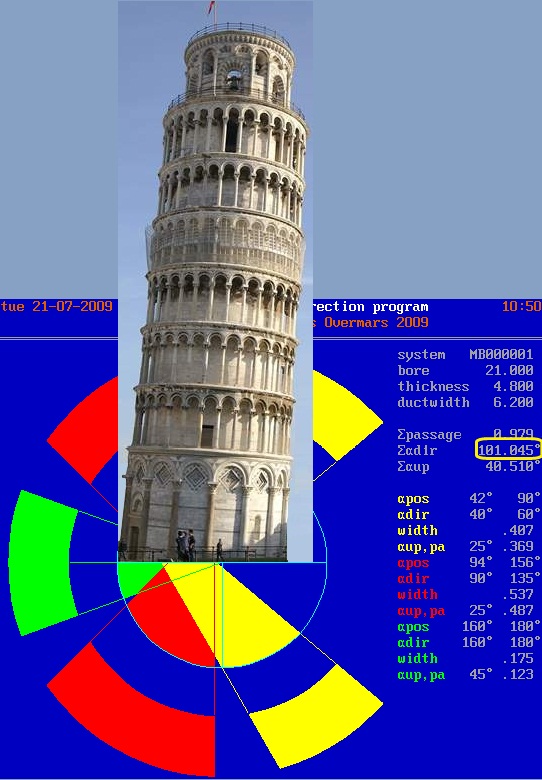

The leaning tower of Pisa

Transfer theory part 1

the central column

We

want ample angle.area for our transfer ports while at the same time

keeping their height within limits, so we need all the transfer area we

can get; we want to use as much as possible of the cylinder

circumference.

The best way to utilize the available real estate

would be to aim all transfers radially inward; that way the cross

section widths of all ports would be equal to their chord widths and you

can't get any better than that. All transfer streams would meet in the

center of the cylinder, slow each other down and form a central column

with only one direction to go: upwards, in the direction of the cylinder

head.

But since you can't have a transfer port at the exhaust side

of the cylinder, an imbalance would occur and that central column would

be inclined (sic) to topple over towards the exhaust side of the

cylinder. You don't want that because too much of the fresh charge would

take the escape route into the exhaust duct without first scavenging

the cylinder.

How do you prevent that central column from leaning

towards the exhaust side? If you omit the transfer ports directly

opposite the exhaust, you would restore the scavenging balance, but you

would sacrifice too much valuable port area. There is a solution, but

let me address some other scavenging aspects first.

We want as

much transfer port area as possible, so it would make sense to have all

transfer ducts enter the cylinder perpendicularly, right? Nope.

To

begin with, most pistons are domed, so transfer flow entering the

cylinder would collide with the dome. Aiming the transfer ducts axially

at about the same angle as the piston dome, usually about 10°, will not

cost any effective cross section area and it will noticeably improve the

flow coefficient. Larger-than-zero axial angles at the port floors will

also enable you to fit larger inner radii in the transfer ducts,

another benefit for the flow.

Second: those transfer streams

entering the cylinder and colliding in the center will convert kinetic

energy into potential energy. In English: their flow velocities will

slow each other down in the collision process and the static pressure in

the middle of the resulting central column will be higher than the

pressure in the transfer ducts.

That static pressure in the central

column is a good thing: it will provide for a higher density of the

fresh charge in the column and that helps to expel the hot, thin burnt

gases from the previous combustion cycle. Think of it as using a jet of

water to chase away smoke: that will work a lot better than the other

way around (using smoke to chase away the water).

But the static

pressure at the foot of the central column can also have adverse

effects. Too high a static pressure will impair the flow, because the

higher this pressure is, the smaller will be the pressure differential

that accelerates the charge through the transfer ducts. Aiming the

transfer ducts axially a little will improve the flow, just like it did

because of the domed piston. Slightly axially-aimed transfer streams

will provide for a less violent, not completely head-on collision. The

central pressure can be controlled this way, and the transfer streams

will keep the axial component of their velocity, so the central column

does not need to begin its journey to the cylinder head with zero

velocity. So the axial column speed can be controlled as well by the

axial transfer angles.

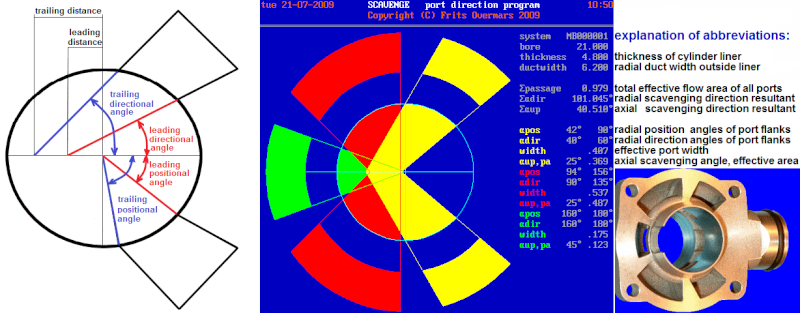

Transfer theory part 2

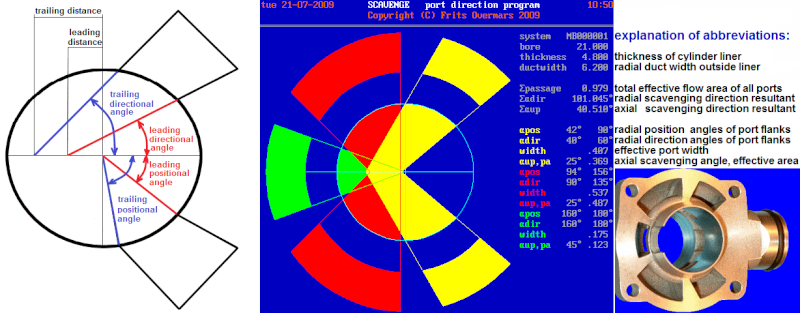

positional & directional scavenging angles

Most

two-stroke people define radial scavenging directions by quoting the

distances where the ports would intersect the center line (the leading

distance and trailing distance in the drawing below left). Gordon Blair

used that notation in his publications, and 95% of us followed suit.

But there is a better, more universally applicable way.

I

will explain with an example, not of scavenging directions but of port

timing: I might say that a transfer port height of 13 mm is perfect for a

racing engine. That may be true for a 125 cc engine but it would be

nonsense for a 50 cc or a 500 cc.

But if I say that a transfer port

timing of 130° is perfect for a racing engine, then that is valid for

any engine, regardless of its cubic capacity. Absolute distance values

(millimeters, inches etc.) are not suitable for universal guidelines.

Degrees are, as are percentages of bore or stroke. Rpm values are not;

mean piston velocities are.

I express transfer duct directions

in degrees. Each duct has a leading flank and a trailing flank. Each

flank intersects the bore at a point which I can define with a

positional angle. And each flank hits the fore-aft center line of the

bore with an included angle which I call the directional angle. The

drawing below left may clarify what I mean. And the drawing on the right

is an example of an existing cylinder.

Now we can express the

radial characteristics of the transfer ports with positional and

directional angles, regardless of bore and stroke.

And we can express

the ports' axial characteristics with axial angles, but that only gives

a 'universal value' for engines with identical bore/stroke-ratios.

We

may quote a height H in the cylinder where the transfer port's roof

would hit the opposite cylinder wall. But we need to express H as a

percentage of the stroke. Then we will have a truly universal value.

Then we will also see that short-stroke engines require smaller axial angles.

Transfer theory part 3

the tower of Pisa

As

we are on the subject of scavenging angles, now would be a good time to

say something about the axial angles of the A-transfers.

Surely a

duct with an axial angle of over 20° offers a smaller cross-section to

the flow than a duct that enters the cylinder perpendicularly?

Yes it does. But there are two good reasons to angle it upward anyway.

First,

perpendicular mixture streams coming from the A-ports would collide and

slow one another right down. The axial angles provide for less velocity

losses and less pressure losses, so despite their smaller

cross-section, upward ports may flow as much, if not more, than

perpendicular ports.

(Now you may well ask why the B-ports do not get

the same treatment. It is because the central scavenging column,

resulting from all incoming scavenging streams together, must not have

too much axial velocity, or the loop scavenging will result in a

loop-loss into the exhaust).

Second, there is a thing called

scavenging balance (I invented the word for my personal use, so this may

well be the first time you ever saw it).

If you looked closely at

the scavenging picture of the MB-cylinder I posted above, you may have

noticed that the 'radial scavenging directional resultant' had a value

of 101,045°.

90° would have meant 'straight up'; more than 90°

indicates that the central scavenging column is leaning towards the

exhaust side of the cylinder.

But we don't want that; it is bad for

the scavenging of the rear part of the cylinder, and it is risky because

it may provoke scavenging losses straight into the exhaust.

But

how can we prevent a scavenging column from toppling over to the

exhaust side like the leaning tower of Pisa? Not by pushing against its

basis, but by pushing higher up. Hence the axial angle of the A-ports.

The pictures will tell the story. (If only the Pisa architect had known a

bit more about two-stroke scavenging....)

Transfer theory part 4

vectors

Let

us assume that all transfer ports are of the same height. Let's also

assume that a port with twice the cross-sectional width will give twice

as strong an impulse (that is already doubtful; it presumes equal

densities and equal flow velocities in all ducts, and as duct contents

can have different inertias, their accelerations may differ, as will

their flow velocities at any given moment).

If you accept these

assumptions, you can resolve each transfer stream into an axial

component, a fore-aft component over the piston, and a left-to-right

component over the piston. The axial components all work in the same

direction: towards the cylinder head. The left-to-right components will

cancel each other out (if they don't the scavenging is asymmetric) while

contributing to the pressure creation at the root of the central column

(which in turn will accelerate the axial flow and thus enhance the

axial vector), and the fore-aft components will result in a vector that

may either point towards the rear side of the cylinder, be zero, or

point towards the exhaust side.

This fore-aft vector together with

the axial vector will give a resultant that will lean towards the rear

of the cylinder, or point straight up towards the head, or lean towards

the exhaust side.

What we want to achieve, is an axial column

that clings to the rear of the cylinder, so it can wash away the spent

gases with as little turbulence as possible. Turbulence will result in

mixing of fresh charge and burnt gases, and we don't need that. And

mixing will heat up the fresh charge, bringing it nearer to the

detonation treshold. And we certainly don't need that!

I realize

this is a crude way of describing a complicated flow dynamics event,

but hopefully it will help you form a mental picture (no pun intended).